.jpg)

Climate protection with recycled tires

Many plastics are extremely difficult to recycle and end up either incinerated or landfilled. This is particularly true of used tires. However, even tires can be recycled and used as an environmentally-friendly alternative to crude oil.

A remarkable achievement for people and planet

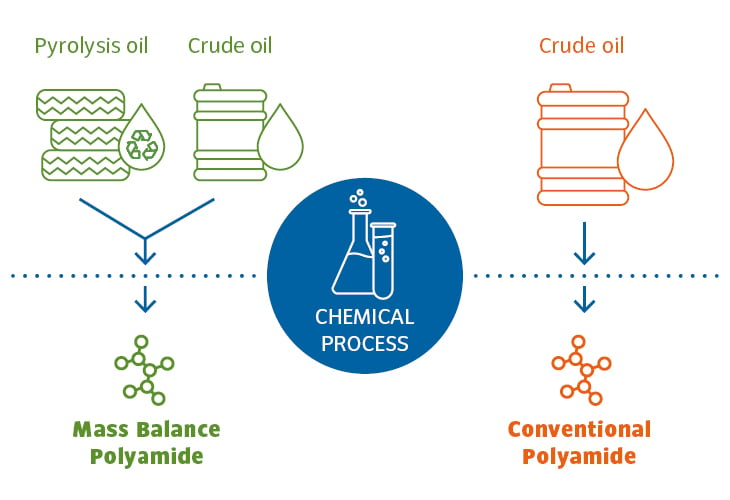

VAUDE is the first company in the outdoor textile sector to use a chemical process technology that produces polyamide from plastics that are difficult to recycle. Thanks to a certified mass balance process, recycled oil from used tires (pyrolysis oil) is integrated into the polyamide production system. To achieve this, the carbon chains contained in the used tires are molecularly broken down and, through chemical transformation, serve as an alternative to crude oil for the production of plastics.

Materials of equivalent quality

As this alternative raw material is introduced into the production plant right at the start of the chemical value chain, the resulting product (as polyamide) has exactly the same qualities as conventionally manufactured products. The major advantage of this method is that these materials can be processed in the same way as before. For example, dyeing processes and other textile treatments do not need to be modified, helping to reduce waste volumes and conserve valuable resources.

Recycling process for used tires

- Men's Farley Stretch T-Zip III pants

- Women's Farley Stretch T-Zip III pants

- Men's Yaras ZO pants

- Women's Yaras ZO pants

Mass balance, a proven approach

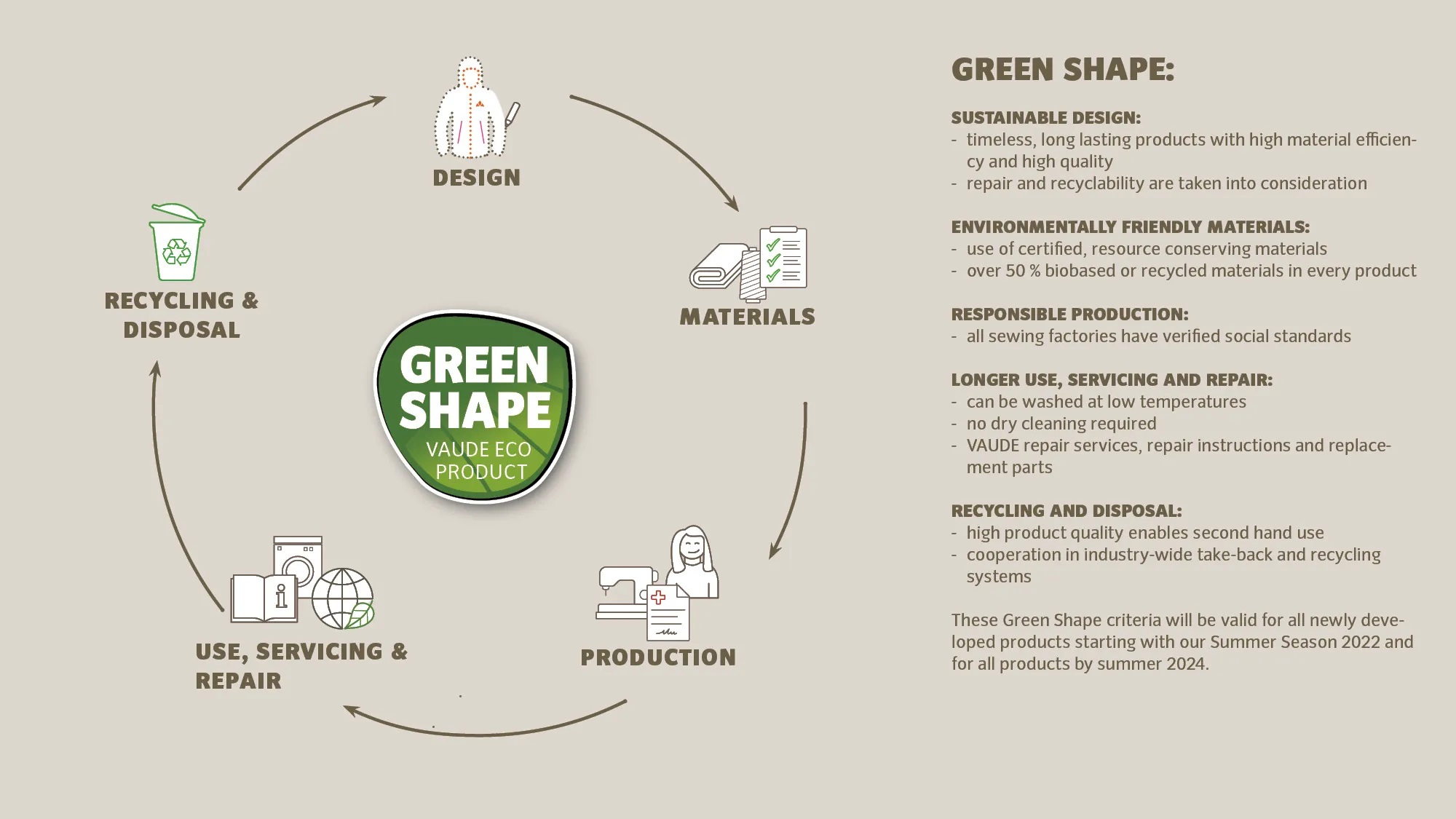

VAUDE: a committed and responsible brand

If you'd like to find out more about Vaude and its commitment to the environment, read our blog post, Vaude, the environmental pioneer.